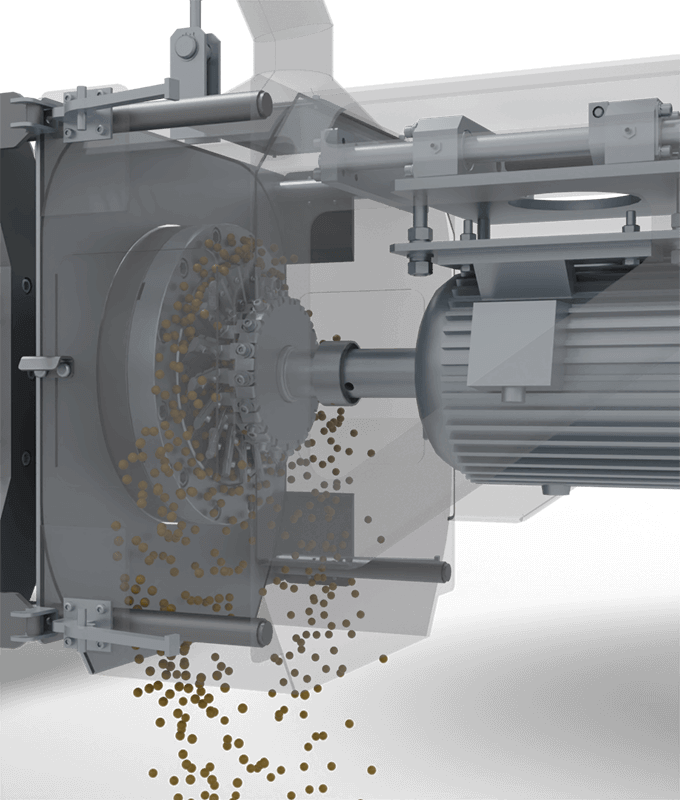

As the aquafeed industry demands higher precision and efficiency, automation has become essential. FAMSUN addresses this need with its Twin-Screw Aqua Extruder, a highly automated fish feed extruder machine that ensures stable, high-quality output with minimal manual intervention. With intelligent modular control and user-friendly operation, it represents a new standard in smart feed production.

Advanced Intelligent Control System

The FAMSUN Twin-Screw Aqua Extruder is equipped with a modular intelligent control system that monitors and manages critical process parameters in real time. Each stage of the production process—from feeding and preheating to conditioning and extrusion—is controlled independently to maintain consistent quality and optimize system performance.

One-Click Operation Modules

Designed for ease of use, the extruder includes standardized automation features such as one-click preheating, one-click conditioning, and one-click startup and shutdown of both the extruder and auxiliary systems. This significantly reduces operator workload, improves production speed, and enhances process stability.

Minimized Labor, Maximized Efficiency

Thanks to its high degree of automation, this fish feed extruder machine reduces the reliance on manual labor while increasing precision and productivity. Automatic mechanical energy control and one-click cleaning further simplify daily operations, allowing producers to focus on efficiency and product development.

Conclusion:

With cutting-edge automation and smart control features, the FAMSUN Twin-Screw Aqua Extruder delivers consistent product quality, reduced labor costs, and streamlined production. As a reliable fish feed extruder machine, it is the ideal solution for modern feed manufacturers seeking to upgrade their operations with intelligent technology.